Image for Illustration purposes only. Actual product may vary

Allen Bradley 22F-A011N113 PowerFlex 4m AC Drive

MODEL 22F-A011N113

$1,190.00 Each

Prices are subject to change

FREE SHIPPING ON ORDERS OVER $1

Select Quantity

Free Gift with this product

Free Gift with this product

Typically Ships in: 1 day

Returnable: Yes

Control panel

Yes

Current rating

11 A

Field bus communication type

ModBus

Filter included

Yes

IP rating

IP20

Mounting type

Panel mount

Output frequency

400Hz

Overall depth

136 mm

Overall Length

174 mm

Overall width

100 mm

Phase

1

Power rating

2.2 kW

Series

PowerFlex 4M

STO

No

Supply voltage

240 V AC

Product Details

Allen Bradley PowerFlex 4M Single-Phase Input Frequency Controllers

Experience powerful and precise motor speed control with PowerFlex 4M Single-Phase Input Frequency Controllers by Allen Bradley. These compact, cost-effective inverter drives are perfectly suited for machine level control. PowerFlex 4M drives offer application flexibility, feed through wiring and ease-of-programming to provide you with a streamlined and highly efficient motor control solution.

This drive is available in three frame sizes: A, B, and C, with power ratings from 0.2 to 11 kW (0.25 to 15 Hp) and in voltage classes of 120, 240 and 480 volts. Its ventilation system is only activated during motor operation, and it is silent when stopped, ensuring long service life.

Features and Benefits:

Pulse Width Modulation Frequency adjustable to 10 kHz for quiet operation

DIN rail mounting feature on A and B frame drives

Integral keypad included

Ambient temperatures up to 50 °C (122 °F) permitted with minimal spacing between drives

Side-by-side Zero Stacking Drives for ambient temperatures up to 40 °C (104 °F)

Integral RS-485 communications

Ingress Protection level of IP20 with open type enclosure and slip compensation for enhanced stability

Drive overload protection and ramp regulation

What is an Inverter Drive?

An Inverter Drive (also known as AC Drive, Variable Frequency Drive, or VFD) is a motor drive device which regulates the amount of power supplied to a motor, allowing for precise control of speed or torque to the motor to suit its application. They are situated between an electrical supply and a motor. Electrical motors run many things we use in our society today and inverter drives are used for speed control in a range of applications, such as simple fan and pump loads. Inverter drives are also used widely in industrial applications for high torque machine control. Most inverter drives now have features such as digital operation and LED displays allowing for easy set-up, monitoring, and adjustment of parameters by the user.

How does an Inverter Drive work?

Inverter drives are controlled by inputting specific frequencies or parameters into the device. When power goes through the drive the inverter adjusts the frequency and voltage that is supplied to the motor. They ensure that an electrical motor receives only the necessary amount of power it requires to function, in order to reduce waste or loss of electrical energy, thereby making it more efficient to run. They can also gradually ramp up power for a slower, safer machine start up. Inside the inverter, incoming AC power is converted to DC power via a rectifier made up of diodes, which is then smoothed to a clean, constant voltage by capacitors, and is then fed back out as AC power via output transistors.

Allen Bradley Inverter Drive, 11A, 2.2kW - PowerFlex 4M Series - 22F-A011N113

Use this powerful inverter drive from Rockwell Automation's Allen Bradley range for accurate motor control in your industrial systems. The device has a removable metal oxide varistor (MOV) for surge voltage suppression, so it can handle sudden voltage spikes for enhanced electrical safety. It also has a strong overload protection system to prevent overheating of the system while in use. This inverter drive has integrated light-emitting diode (LED) indicators that display its running conditions, making it easy to detect faults and troubleshoot. You'll find it used in process control operations and packaging industries.

Power rating of 2.2kW for use with single-phase motorsWide operating temperature range of between -10°C and +50°C for reliable performance in harsh environmentsCompact dimensions of 174 (length), 100 (width) and 136mm (depth) for space efficiency in tight enclosuresEasy DIN mounting to save times

Standards and Certifications

IEC (International Electrotechnical Commission)UL (Underwriters' Laboratory)RoHS (Restriction of Hazardous Substances)

How do I maintain this inverter drive?

You should clean the drive regularly to remove dust, check its connections to ensure they're tight and replace any component parts that have a short life cycle, such as fuses. You should also regularly back it up to your computer.

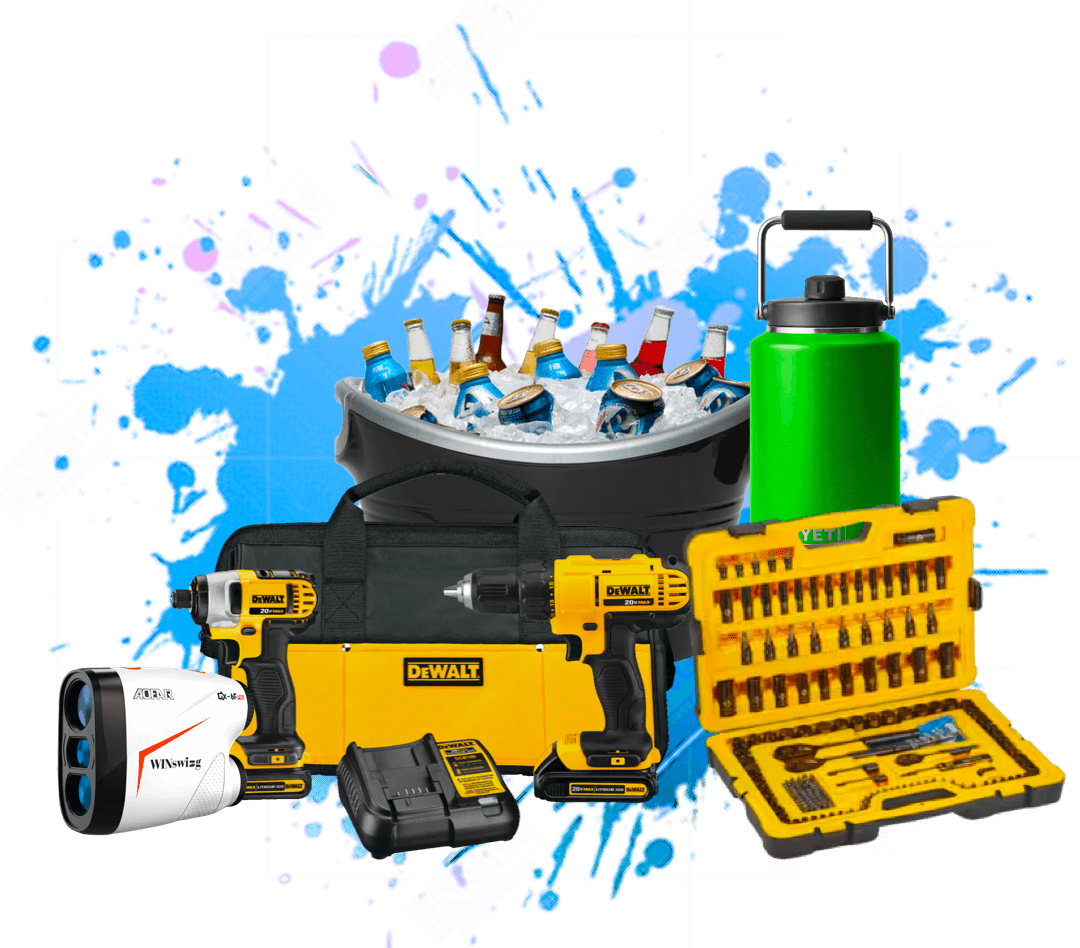

When you get to checkout, you’ll be able to select a free gift! Depending on the cart value, you’ll be shown relevant gifts your order qualifies for.

$500

MRO Hat

MRO Golf Balls

MRO Hi-Vis Vests

MRO Mug

$750

32oz Water Bottle

Throw Blanket

30 piece Hex Set

Telescopic Pick Up

$1,250

Golf Cooler

11-in-1 Screw Driver Set

Gorilla Grip Knee Pad

John Deere Oilskin Hat

$2,500

Igloo 1/2 Gallon Jug

Rechargable Headlamp

Larix Trucker Hat

$5,000

Igloo 10 Gallon Cooler

Igloo Party Bucket Cooler

Klein Tools Speaker

Klein Tools 8-in-1

$7,500

GX-6F Pro Golf Range Finder

Bushnell Outdoorsman Speaker

Jaeger 24px Ratcheting Wrench Set

Aspen Beverage Bucket