Image for Illustration purposes only. Actual product may vary

TIMKEN 2786-2 TRB Single Cone <4 OD

MODEL 2786-2

This vendor has a minimum order quantity of 3. Order minimum ($) may be applied. Add desired QTY to cart and proceed to checkout to view minimum

$55.89 Each

Prices are subject to change

FREE SHIPPING ON ORDERS OVER $1

Select Quantity

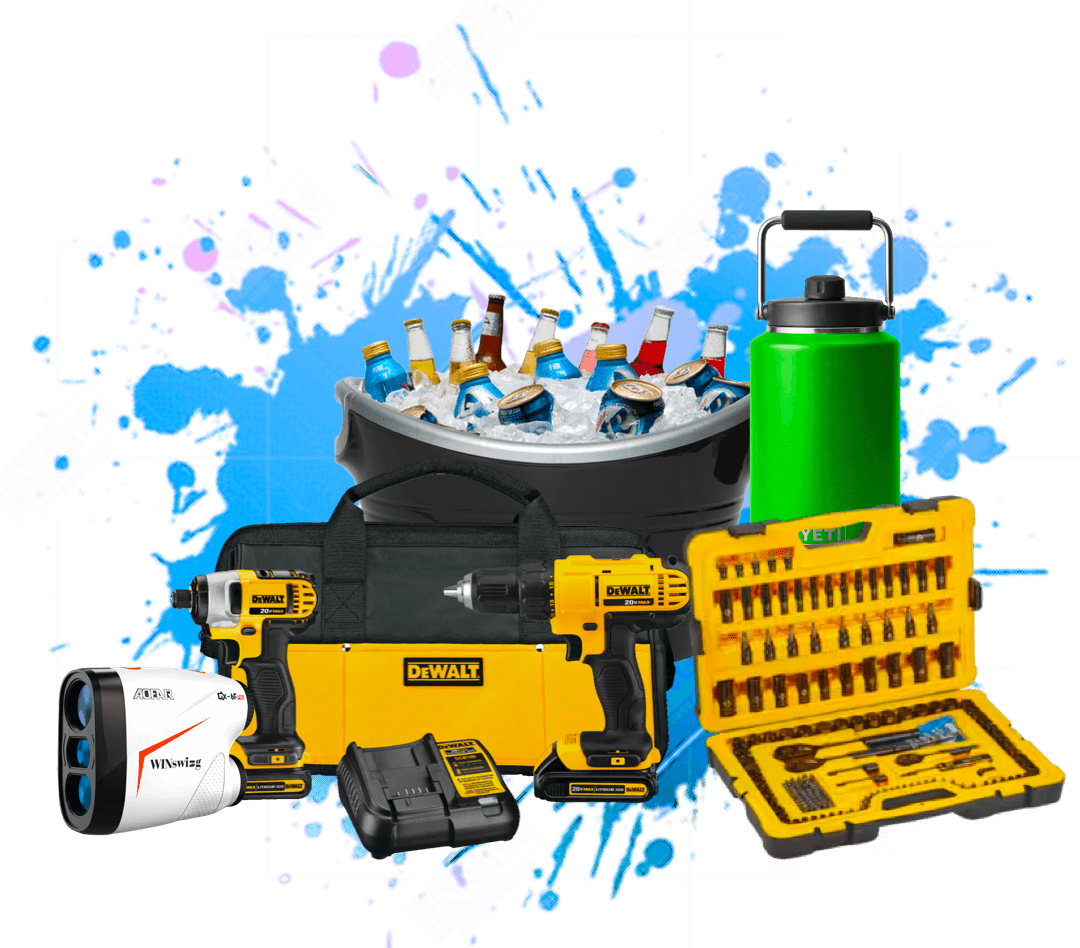

Orders over $500 qualify for a Free Gift

Orders over $500 qualify for a Free Gift

Brand Minimum Order Quantity: 3

Typically Ships in: 1 day

Returnable: Yes

79.50 mm Dimension D2

2.880 in

Belt Size

Any B Type

Bore Diameter

1 1/8 in

Cubic inches

202.37000 in³

Description

7030 1-1/8 PULLEY

Drive Type

Adjustable CenteDriver

Keyway Size

1/4 x 1/8 in

Model

7030

Motor Power at 1, 150 rpm

2.00 hp

Motor Power at 1, 750 rpm

3.00 hp

Outside Diameter

7.000 in

Overall Length

4.130 in

Ratio

1.80:1

Torque Capacity

108.00 in·lb

Total Travel Distance

2.200 in

UPC Number

27862

One-Side Moveable

1/3 Through 5 HP, “A” and “B” Belts

The Econoline Pulley series provides reliable variable speed service with a proven design at an economical cost. The wide selection of models feature compact size and reliability, which make them ideal for both adjustable and fixed center drives in all types of applications using classical “A” and “B” (or 4L and 5L) section drive belts.

Spring-loaded pulleys are through-bored for all types of shaft mounting arrangements. The exposed spring design allows for a cooler running pulley and permits easy cleaning. Complete spring enclosures are available as an option on some models.

Belt Selection

Econoline pulleys are designed specifically for “A” and “B” section drive belts, though they can also be used with “4L” and “5L” belts if necessary. Cogged, raw-edge belts have a definite advantage over wrapped types because they readily form around small pitch diameters, and provide a better arc of contact and provide best possible transmission of torque. If a “slip clutching” effect is desirable to protect machinery in the event of overload, a wrapped belt is recommended.

Adjustable Center Drives

An adjustable center drive using the Econoline variable speed driver pulley is an economical, efficient solution for many drive requirements. The typical adjustable center drive consists of a spring-loaded pulley mounted on the motor shaft, a companion sheave on the driven shaft, an adjustable motor base, and a belt. A wide range of sizes and horsepower ratings are available from the Econoline series to fit the system requirements.

Standard “A” and “B” companion sheaves are recommended for use with Econoline adjustable center drives. Since many Econoline pulleys have only one moveable flange and the companion sheaves are grooved, some misalignment of the belt can be expected and is acceptable for most drives. To minimize this misalignment, the belt should be aligned with the driven sheave when the belt is in the median pitch diameter range of the variable speed pulley, or in the range of principle operation. Due to the minimal bottom contact area of “A” and “B” belts, flat driven sheaves are NOT recommended.

Fixed Center Drives

Econoline fixed center drives utilize the same type of spring-loaded pulley as an adjustable center drive, only it is normally mounted on the driven shaft. The driver pulley is of similar size and construction, but it is manually adjustable. A fixed center drive offers greater driven speed range in a more compact space. There are two types of controllable pulleys: the M type with a hand wheel and built-in adjusting device, and the MLA type that uses an external control. The MLA type pulley can be used with the Lovejoy #76 Control Stand (see page VSD-21) or some other type of linear controller.

A fixed center drive consists of four component parts: the adjustable driver pulley, the spring-loaded driven pulley, the belt, and a Model 501 Torque Arm Bracket. This bracket prevents the handwheel from spinning so speed can be changed while the drive is running (see drawing on page VSD-21). The 501 Torque Arm Bracket is NOT needed with the MLA type pulley. A wide variety of drive packages are available from the Econoline Series to suit your needs. Different diameter pulleys can be paired together to achieve a variety of driven speed ranges, and all sizes of driven spring- loaded pulleys are available in a variety of horsepower ratings.

SKU: 5066946

Best company to buy from

I always buy from MRO is a very reliable company to work with

Read moreWhen you get to checkout, you’ll be able to select a free gift! Depending on the cart value, you’ll be shown relevant gifts your order qualifies for.

$500

MRO Hat

MRO Golf Balls

MRO Hi-Vis Vests

MRO Mug

$750

32oz Water Bottle

Throw Blanket

30 piece Hex Set

Telescopic Pick Up

$1,250

Golf Cooler

11-in-1 Screw Driver Set

Gorilla Grip Knee Pad

John Deere Oilskin Hat

$2,500

Igloo 1/2 Gallon Jug

Rechargable Headlamp

Larix Trucker Hat

$5,000

Igloo 10 Gallon Cooler

Igloo Party Bucket Cooler

Klein Tools Speaker

Klein Tools 8-in-1

$7,500

GX-6F Pro Golf Range Finder

Bushnell Outdoorsman Speaker

Jaeger 24px Ratcheting Wrench Set

Aspen Beverage Bucket

SKU: 5066946

Best company to buy from

I always buy from MRO is a very reliable company to work with

Read more