Image for Illustration purposes only. Actual product may vary

BALDOR VFSWDM3550T-E 1.5HP 3500RPM 3PH 60HZ 143TC 3532M TENV

MODEL VFSWDM3550T-E

Contact supplier for technical support on: 323 724 6771

$1,839.38 Each

Prices are subject to change

FREE SHIPPING ON ORDERS OVER $1

Select Quantity

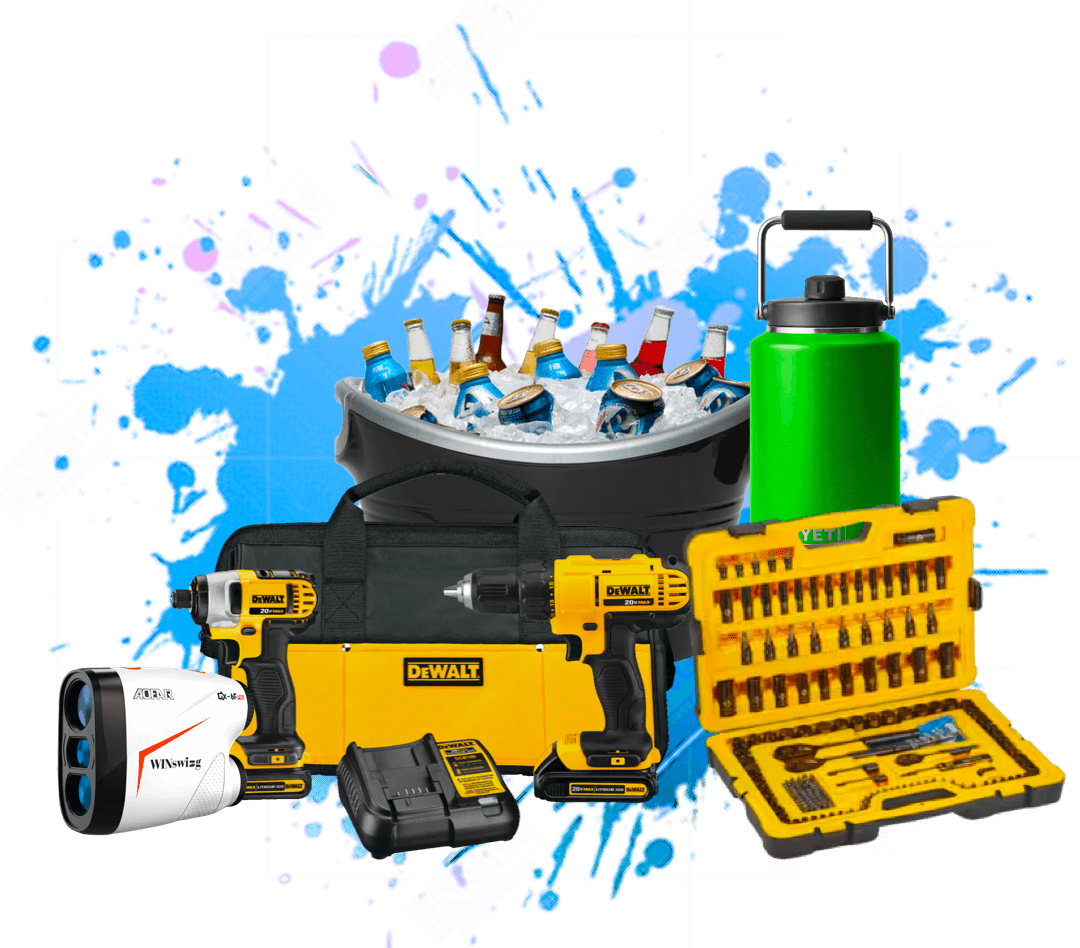

Free Gift with this product

Free Gift with this product

Typically Ships in: 1 day

Returnable: See conditions

Agency Approvals

NEMA_PREMIUM

Ambient Temperature

40°C

Auxillary Box

NoAuxillaryBox

Auxillary Box Lead Termination

None

Base Indicator

NoMounting

Bearing Grease Type

PolyrexEM(-20F+300F)

Blower

None

Break-Down Torque

10.9LB-FT

Current @ Voltage

3.600A@230.0V

Design Code

B

Drip Cover

NoDripCover

Duty Rating

CONT

Efficiency @ 100% Load

85.5%

Electrically Isolated Bearing

NotElectricallyIsolated

Enclosure

TENV

Feedback Device

NOFEEDBACK

Frame

143TC

Frame Material

StainlessSteel

Frequency

60.00Hz

Front Face Code

Standard

Front Shaft Indicator

None

Full Load Torque

0LB-FT

Heater Indicator

NoHeater

High Voltage Full Load Amps

1.8a

HP

1.5

Hz

60

Insulation Class

H

Inverter Code

InverterReady

KVA Code

M

Lifting Lugs

NoLiftingLugs

Line-Line Res. @ 25° C

7.64OhmsAPh/0OhmsBPh

Locked Bearing Indicator

LockedBearing

Locked-Rotor Torque

10.2LB-FT

Motor Finish

UNPAINTED

Motor Lead Exit

KoBox

Motor Lead Quantity/Wire Size

@0AWG

Motor Lead Termination

FlyingLeads

Motor Letter Type

ThreePhase

Motor Standards

NEMA

Motor Type

3532M

Mounting Arrangement

F1

No-Load Current

0A

Number of Poles

2

Output @ Frequency

1.500HP@60HZ

Overall Length

13.72IN

Phase

3

Power Factor

90

Product Family

WDAllSSEncapsulated

Pull-Up Torque

5.2LB-FT

Pulley End Bearing Type

SealedBearing

Pulley Face Code

C-Face

Pulley Shaft Indicator

Standard

Rodent Screen

None

RoHS Status

ROHSCOMPLIANT

RPM

3400 - 3600

Service Factor

1.15

Shaft Diameter

0.875IN

Shaft Extension Location

PulleyEnd

Shaft Ground Indicator

NoShaftGrounding

Shaft Rotation

Reversible

Shaft Slinger Indicator

NoSlinger

Speed

3500rpm

Speed Code

SingleSpeed

Start Configuration

DOL

Starting Current

20.6A

Starting Method

Directonline

Synchronous Speed @ Frequency

3600RPM@60HZ

Temp. Rise @ Rated Load

78°C

Temp. Rise @ S.F. Load

90°C

Thermal Device - Bearing

None

Thermal Device - Winding

None

Vibration Sensor Indicator

NoVibrationSensor

Voltage

230/460

Voltage @ Frequency

460.0V@60HZ

Winding Thermal 1

None

Winding Thermal 2

None

XP Class and Group

None

XP Division

NotApplicable

When you install an electric motor, it is important to maintain it well to prevent damages that can reduce productivity, cause danger and reduce its lifespan. Note that all of these impacts result to increased cost of operations. Therefore, you should ensure that the motors are installed well, serviced regularly and performance monitored to identify any issue that can damage them early.

Read MoreWhen you get to checkout, you’ll be able to select a free gift! Depending on the cart value, you’ll be shown relevant gifts your order qualifies for.

$500

MRO Hat

MRO Golf Balls

MRO Hi-Vis Vests

MRO Mug

$750

32oz Water Bottle

Throw Blanket

30 piece Hex Set

Telescopic Pick Up

$1,250

Golf Cooler

11-in-1 Screw Driver Set

Gorilla Grip Knee Pad

John Deere Oilskin Hat

$2,500

Igloo 1/2 Gallon Jug

Rechargable Headlamp

Larix Trucker Hat

$5,000

Igloo 10 Gallon Cooler

Igloo Party Bucket Cooler

Klein Tools Speaker

Klein Tools 8-in-1

$7,500

GX-6F Pro Golf Range Finder

Bushnell Outdoorsman Speaker

Jaeger 24px Ratcheting Wrench Set

Aspen Beverage Bucket

Item must be unused.

Item must be in it's original package.

Restocking, shipping and handling fees may apply to any return with this manufacturer.

For more information please consult https://www.mrosupply.com/page/returnwarranty-policy/