Image for Illustration purposes only. Actual product may vary

Dixon

R96P2LJR15 Holedall® Floating Flange Assembly

Dixon R96P2LJR15 Holedall® Floating Flange AssemblyMODEL R96P2LJR15

Contact supplier for technical support on: 8779634966

$1,020.87 Each

Prices are subject to change

FREE SHIPPING ON ORDERS OVER $1

Select Quantity

Free Gift with this product

Free Gift with this product

Typically Ships in: 1 day

Returnable: See conditions

California Prop 65 warningHose I.D.

6 in

Hose OD From

7-5/64 in

Hose OD To

7-12/64 in

Material

316 Stainless steel

Construction

- 316 stainless steel stem and flange

- Carbon steel ferrule

Features

- 150# ASA flange drilling

- The Holedall coupling provides long-lasting efficiency and safety.

- The coupling system requires no bolts and results in a clean coupling with no protrusions.

How It Works

- The hydraulic swaging of the coupling to the hose is accomplished by pushing the ferrule through a die which reduces the ferrule OD, thus providing a 360° uninterrupted compression band around the hose.

- A hydraulic ram is the only piece of machinery necessary to accomplish the coupling. Rams are available in five different sizes- 15,25, 50,100 and 350 ton - these rams will accommodate dies and pushers of various sizes so that hoses up to 10" in diameter may be coupled.

- Couplings can be swaged or crimped.

Safety Notes

- Dixon Holedall stems and ferrules are specifically designed to be used together as a coupling system.

- Due to differences in dimensions and tolerances, for safety reasons, do not use other manufacturer's stems or ferrules with Dixon Holedall products.

- Do not use a wrench or vice on ferrule

- Holedall couplings, regardless of coupling style, are never to be used for steam service at any pressure.

- Holedall fittings are not to be used with cable reinforced high-pressure hose, 4 or 6 braid wire hydraulic hose or any other service not listed in the recommendations. Consult Dixon for recommendations on usage.

- Externally swaged Holedall couplings, to perform satisfactorily, must be applied properly in accordance with Dixon's assembly procedures, using correct die and ferrule for that particular hose end OD. Dixon's Die and Ferrule Recommendation Guide is to be used to select correct dies and ferrules. Consult Dixon if you do not have an updated Die and Ferrule Recommendation Guide.

- Hose service working pressure (including surges and spikes) is never to exceed the maximum recommended working pressure for the fitting. The assembly's (hose + coupling) maximum working pressure is the lesser of the hose rated working pressure or the coupling rated working pressure.

- Media being transported through the hose should be compatible with the stem material. Compatibility of ferrule material with the environment in which it will be used is recommended. Consult the Compatibility Chart or contact Dixon for material compatibility.

- For applications other than the ones list, please consult Dixon.

SKU: 2933866

Dixon 6hf6-b 3/4" iso-b coupler 3/4" nptf bras 200025-6

Great price, fast delivery.

Read moreSKU: 115099

Reasonable and reasonably fast shipping

My order was processed very quickly even with the changes I made on my original order with friendly people at MRO

Read moreSKU: 2933980

Dixon 8hf8-b 1" iso-b coupler 1" nptf brass 200025-8

Great price, fast delivery.

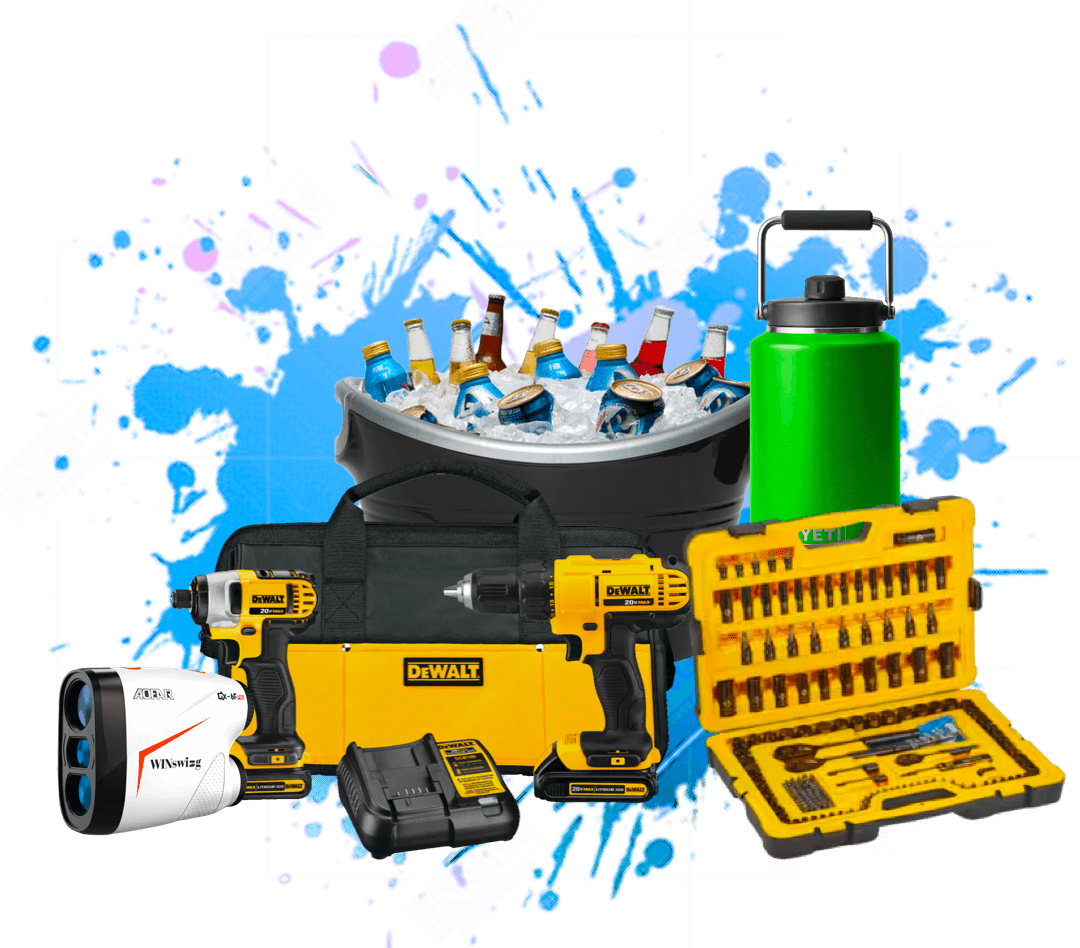

Read moreWhen you get to checkout, you’ll be able to select a free gift! Depending on the cart value, you’ll be shown relevant gifts your order qualifies for.

$500

MRO Hat

MRO Golf Balls

MRO Hi-Vis Vests

MRO Mug

$750

32oz Water Bottle

Throw Blanket

30 piece Hex Set

Telescopic Pick Up

$1,250

Golf Cooler

11-in-1 Screw Driver Set

Gorilla Grip Knee Pad

John Deere Oilskin Hat

$2,500

Igloo 1/2 Gallon Jug

Rechargable Headlamp

Larix Trucker Hat

$5,000

Igloo 10 Gallon Cooler

Igloo Party Bucket Cooler

Klein Tools Speaker

Klein Tools 8-in-1

$7,500

GX-6F Pro Golf Range Finder

Bushnell Outdoorsman Speaker

Jaeger 24px Ratcheting Wrench Set

Aspen Beverage Bucket

SKU: 2933866

Dixon 6hf6-b 3/4" iso-b coupler 3/4" nptf bras 200025-6

Great price, fast delivery.

Read moreSKU: 115099

Reasonable and reasonably fast shipping

My order was processed very quickly even with the changes I made on my original order with friendly people at MRO

Read moreSKU: 2933980

Dixon 8hf8-b 1" iso-b coupler 1" nptf brass 200025-8

Great price, fast delivery.

Read more