Image for Illustration purposes only. Actual product may vary

SPX 110102 SWING CLAMP-BLOCK-LEFT-FORCE 1-610L

MODEL SPX 110102

Contact supplier for technical support on: 800-477-8326

$2,040.85 Each

Prices are subject to change

FREE SHIPPING ON ORDERS OVER $1

Select Quantity

Free Gift with this product

Free Gift with this product

Typically Ships in: 1 day

Returnable:No

Action Type

Double Acting

Clamping Force (lbs)

1610

Direction Of Rotation

Left

Length (in)

5.938

Max Adjustment Range (in)

1.5

Max Flow Rate (cu in/min)

45

Max Swing Speed (sec)

0.25

Retract Port Size

7/16-20UNF SAE-4

Stroke Length (in)

0.31

Width (in)

2.75

Features

Single-screw mounting and the adjustable clamping screw make these clamps easy to reposition on the fixture to adapt to various workpiece sizes, and make set-up and adjustment faster than other methods. It also lets you clamp several workpiece sizes without changing the fixture each time. When mounted on a T-slot machine table, the need for fixtures is often eliminated.

Two separate actuators are used to perform the clamping function. First, a cylinder is used to swing the clamping arm 90° into position over the workpiece. Then a second cylinder is sequenced to pivot the clamping arm into contact with the workpiece and hold it in place.

Twelve clamps are available with maximum clamping forces of up to 8,295 lbs.: six with right hand and six with left hand swing. Minimum operating pressure is 500 psi, maximum is 3,500 psi.

- Single or double-acting (See Threaded Body Style - 365 lbs.)

- Single screw mounting

- Internal sequence valve

- Adjustable clamping screw

- T-slot mountable

- SAE and NPT ported versions

Swing Clamp Modification Information

- Standard arm may be customized for use in specific applications.

- Standard clamping arm is 1045 steel heat treated to 38 Rc max.

- Modified/custom-designed clamping arms must be spring biased or counter weighted so that the arm pivots away from the workpiece.

- Arms must be stopped such that they do not pivot below the retracted height of the clamping cylinder.

Note: Modified arms may not have the same workpiece clamping force as standard clamps. Clamping force may be calculated by using the dimensions and cylinder force data below. Any clamp using a modified or custom arm that is longer or heavier than the standard arm, must have its flow restricted to prevent internal damage.

SKU: 1966869

Mro product supply

Thanks MROSUPPLY, fair prices and good stock, fast shipping and communication. Always the first stop for tooling and supplies.

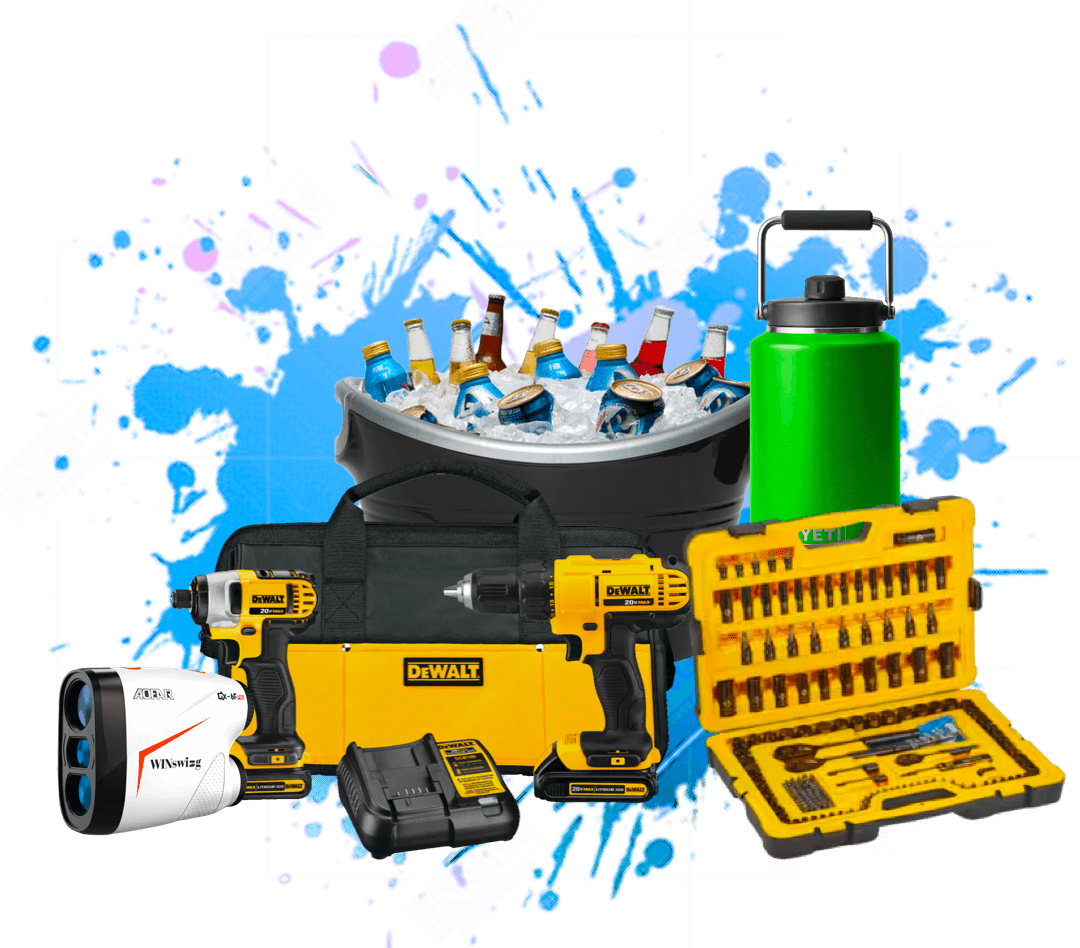

Read moreWhen you get to checkout, you’ll be able to select a free gift! Depending on the cart value, you’ll be shown relevant gifts your order qualifies for.

$500

MRO Hat

MRO Golf Balls

MRO Hi-Vis Vests

MRO Mug

$750

32oz Water Bottle

Throw Blanket

30 piece Hex Set

Telescopic Pick Up

$1,250

Golf Cooler

11-in-1 Screw Driver Set

Gorilla Grip Knee Pad

John Deere Oilskin Hat

$2,500

Igloo 1/2 Gallon Jug

Rechargable Headlamp

Larix Trucker Hat

$5,000

Igloo 10 Gallon Cooler

Igloo Party Bucket Cooler

Klein Tools Speaker

Klein Tools 8-in-1

$7,500

GX-6F Pro Golf Range Finder

Bushnell Outdoorsman Speaker

Jaeger 24px Ratcheting Wrench Set

Aspen Beverage Bucket

SKU: 1966869

Mro product supply

Thanks MROSUPPLY, fair prices and good stock, fast shipping and communication. Always the first stop for tooling and supplies.

Read moreDisclaimer: The return policy information shown below is merely a copy of the text as stated in IDC-USA's Annual Return Policy.

File: http://documents.mrosupply.com/file_uploads/IDCreturnpolicy.pdf

ANNUAL RETURN POLICY PURPOSE: The purpose of IDC-USA’s Annual Return Policy is to allow IDC Distributors the opportunity to return salable stock merchandise of current design that may not have adequate “turns” and replace it with faster moving product.

ACCEPTANCE: IDC Owner-Distributors shall submit a return list to IDC-USA with all pertinent information as follows:

a. Product brand name

b. Quantity

c. IDC-USA’s product identification number

d. Corresponding distributor’s P.O. number or invoice number Acceptance of return shall be subject to IDC-USA inventory levels and manufacturer’s restrictions.

AUTHORIZATION: The return shall be audited and the IDC Owner-Distributor will receive an approved return list with a Return Material Authorization (RMA) number assigned to it. RETURN DATE: Each owner-distributor shall be assigned a month during which they shall be entitled to make a single annual return.

Product Qualification: All products returned must be:

a. On the current price list

b. In good resale condition

c. In the original packaging

d. Purchased from IDC-USA within 3 years of the return

e. Stock items only; no special order items

f. Only those items which have been approved

VALUE: The IDC Owner-Distributor shall receive a credit not to exceed 5% of the owner-distributor’s prior year annual purchases from the IDC Distribution Center. Credit received shall be the actual purchase price or price in effect at the time of the return, whichever is lowest, less applicable restocking charges. Additionally, all annual returns must have a minimum return value of $100.

RESTOCKING CHARGES: There will be a 15% restocking fee unless return is offset by a noncancelable order of equal value to be placed at the time of return. All items received that are not in their original box shall be subject to an additional 15% repackaging fee.

FREIGHT: Returns will be made freight prepaid by the IDC Owner-Distributor to the IDC Distribution Center. The packing slip and all cartons must reference the RMA number. The owner-distributor will be notified of any items received that do not qualify as set forth above. Those items will not be credited and shall be scrapped unless the IDC Owner-Distributor directs otherwise and assumes any additional transportation charges.